1738 various type wells have been delivered successfully domestic and overseas since 2006.

70 percent of the employees are from international recognizable oilfield service companies. There are 56 employees, including 10 senior engineers, 31 oilfield service engineers and 11 repair and maintenance technicians. Accurate rotary geosteering technology leads to efficient, cost-effective drilling optimizations to deliver optimal reservoir development solutions to our clients.

#OILFIELD DIRECTIONAL DRILLING PROFESSIONAL#

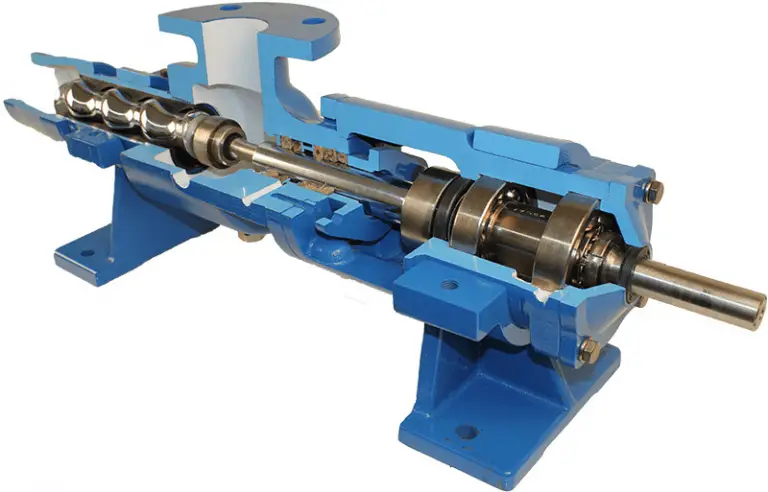

With easy access to aftermarket parts and consumables, HDD companies can trust they have a truly reliable pump at a lower total cost of ownership (TCO).ZPEC directional drilling department is very experienced and professional team that provides clients with comprehensive, high-precision, tailored well trajectory control, technology services, excellent wellbore which is very helpful for casing-running and cementing. It’s all-in service of ensuring that every HDD pump you get from GD Energy Products meets our performance standards and exceeds yours. We have field service technicians who can come to you with solutions, as well as 24-hour customer service and our Parts on Demand program that ensures you never run out of pump parts when you need them. Partnering with GD Energy Products for your HDD equipment also means having an expert team to support you throughout the lifecycle of your pump. With max rod loads ratings up to 53,000 and horsepower up to 800 BHP, our HDD high flow pumps can handle tough jobs with ease. Our lineup of dedicated high pressure HDD pumps come in a lightweight design that eases the burden of transportation and setup while also maximizing their power potential.

Through this more efficient operation, we can help extend the life of our pumps and consumable parts, even in the most demanding HDD projects. Our HDD industry pumps offer higher flow rates at slower speeds, ranging from 200 to more than 1000 gpm at pressures exceeding 2000 PSI.

Horizontal directional drilling pumps-also known as drill pumps, HDD mud pumps, and high flow pumps-provide an essential service to the HDD industry. Equipment manufacturers and end-users can trust our +160 years of experience manufacturing pumps for both petroleum and industrial industries. Therefore, most jobs come with a challenging set of parameters that demand high rates of accuracy, efficiency, and effectiveness. HDD is a process usually deployed when installing pipes and cables underneath roads, rivers and other types of infrastructure.

The mud extracted from this process is then filtered and reused for drilling fluid. As the drill bit is rotating, the pressure and fluid produced by the drill pump helps stabilize the tunnel. As the process comes to life, the drilling pump rotates the drill bit which then removes the material. The process involves boring a tunnel beneath the surface where trenching is not practical.īoring underground requires drilling fluid that combines water and bentonite clay to help remove cuttings, stabilize the bore, cool the cutting tools, and lubricate pipe string. Horizontal Directional Drilling (HDD) is a trenchless method for installing pipes and cables underground. All Applications Acidizing Cementing Coiled Tubing Mud Electric Fracturing Horizontal Directional Drilling Hydraulic Fracturing Industrial Cleaning Mine Dewatering Salt Water Disposal Hydrostatic Testing Trenchless Technology for Underground Construction

0 kommentar(er)

0 kommentar(er)